PCB Etching Tutorial: Difference between revisions

No edit summary |

(UNDO BRA SIZE COPYPASTA VANDALISM| Undo revision 54459 by 45.62.227.7 (talk)) |

||

| (30 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

== '''DIY PCB Etching : Using Chemicals''' == | |||

This tutorial will show you how to make a simple single sided PCB using a chemical method. | |||

In summary the traces will be transferred and covered in a solid copper board , then the parts of copper not needed will stay exposed. | |||

Finally the parts not needed will be removed with chemicals. | |||

[[File:PcbDone.jpg]] | |||

== '''Materials Needed''' == | |||

* Single sided copper clad board -- [[ https://www.google.com/search?q=copper+clad+fr4&ie=utf-8&oe=utf-8]] | |||

* Circuit board trace layout in a printable format (pdf or postscript ps works, design this with an [[EDA | EDA program]]) | |||

* Glossy Inkjet Photo Paper (to print the traces on) | |||

* Iron or press | |||

* Etchant chemical | |||

*# Ferric Chloride Solution (to dissolve the copper from the board) | |||

*# Muriatic Acid | |||

* WetorDry paper | |||

* Container to put PCB in with chemical solution | |||

== '''Steps''' == | == '''Steps''' == | ||

''If you are using Ferric Chloride(FeCl3) foretchant, then start heating your etchant to 50C'' | |||

| Line 34: | Line 33: | ||

Make sure to clean any junk from the copper board before beginning the process! | Make sure to clean any junk from the copper board before beginning the process! | ||

* Use WetorDry paper / fine sand paper to clean the PCB under water until it turns pink | |||

[[File:Sandingboard.jpg]] | |||

[ | |||

* Wipe off water with a clean towel | |||

* Use acetone to remove oils from PCB | |||

[[File:AcetoneClean2.jpg]] | |||

| Line 44: | Line 48: | ||

'''2) Printing the Traces:''' | '''2) Printing the Traces:''' | ||

Grab your printer and print the traces onto the glossy | Grab your Laser printer and print the traces onto the glossy inkjet photo paper. | ||

* we used walgreens 8.5x11 stock inkjet photo paper with fine results | |||

* We used the Noisebridge Brother HL-5470DW and generic Laser printer toner with fine results | |||

* Make sure your print driver isn't scaling or distorting the circuit layout | |||

* Use monochrome and highest resolution possible for your printer | |||

The printer operator should also take this opportunity to provide feedback to the circuit designer: | |||

* Make sure the design traces are thick enough for this process (XXmil/XXmm minimum trace width with 20mil/0.508mm minimum clearance) | |||

* Make sure the export file is mirrored. The Laser Printer toner is going to 'transfer' to the surface of the copper clad and become unmmirrored in the process | |||

[[File:Tracesprinted.jpg]] | |||

'''3) Transferring the Traces to the PCB:''' | '''3) Transferring the Traces to the PCB:''' | ||

*Press down the glossy paper with the design onto the copper PCB | |||

[[File:Tracestransfer.jpg]] | |||

*Use a hot iron to press down glossy paper to the PCB | |||

[[File:Tracestransfer2.jpg]] | |||

*After the glossy paper stick onto the PCB submerge the two in a tray of water and gently press down the paper so it peels off leaving the trace on the PCB | |||

[[File:Traceswaterdip.jpg]] | |||

*Once the paper starts to peel off under the water feel free to use your finger to gently peel the paper from the copper board | |||

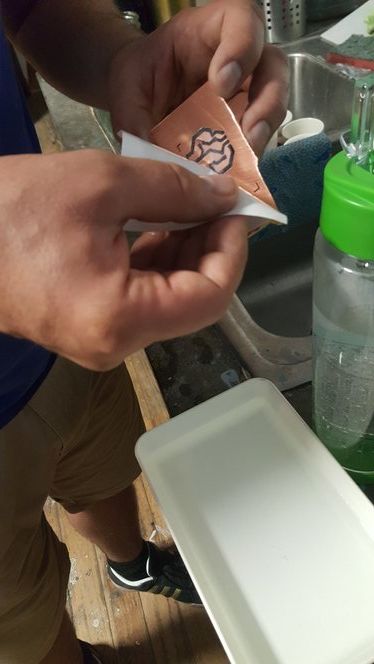

[[File:Tracespeel.jpg]] | |||

*If after peeling the paper , white paper is still on the board re-dip the board into the water and rub off the remaining paper with your finger | |||

[[File:Tracesrewater.jpg]] | |||

*Dry off any water | |||

'''4) Get Rid of the remaining Copper''' | |||

*Place the board into a tray | |||

[[File:Chemicalprep.jpg]] | |||

*Place the Ferric Chloride Solution Bottle inside tray of hot water (this will heat the solution and make the PCB copper to be dissolved faster) | |||

[[File:Heatingchemicals.jpg]] | |||

* Pour some of the solution into a tray along with your PCB | |||

[[File:Chemicaladdit.jpg]] | |||

* Check the PCB every 5 or so minutes to check if the copper has been fully removed | |||

[[File:Chemicalalmostdone.jpg]] | |||

'''5) Finishing Up''' | |||

* Finally wash off the ink and you should be left with only copper lines on top of the traces printed | |||

[[File:PcbDone.jpg]] | |||

Latest revision as of 16:33, 23 May 2017

DIY PCB Etching : Using Chemicals[edit]

This tutorial will show you how to make a simple single sided PCB using a chemical method. In summary the traces will be transferred and covered in a solid copper board , then the parts of copper not needed will stay exposed. Finally the parts not needed will be removed with chemicals.

Materials Needed[edit]

- Single sided copper clad board -- [[ https://www.google.com/search?q=copper+clad+fr4&ie=utf-8&oe=utf-8]]

- Circuit board trace layout in a printable format (pdf or postscript ps works, design this with an EDA program)

- Glossy Inkjet Photo Paper (to print the traces on)

- Iron or press

- Etchant chemical

- Ferric Chloride Solution (to dissolve the copper from the board)

- Muriatic Acid

- WetorDry paper

- Container to put PCB in with chemical solution

Steps[edit]

If you are using Ferric Chloride(FeCl3) foretchant, then start heating your etchant to 50C

1) Preparing the Copper Board: Clean It

Make sure to clean any junk from the copper board before beginning the process!

- Use WetorDry paper / fine sand paper to clean the PCB under water until it turns pink

- Wipe off water with a clean towel

- Use acetone to remove oils from PCB

2) Printing the Traces:

Grab your Laser printer and print the traces onto the glossy inkjet photo paper.

- we used walgreens 8.5x11 stock inkjet photo paper with fine results

- We used the Noisebridge Brother HL-5470DW and generic Laser printer toner with fine results

- Make sure your print driver isn't scaling or distorting the circuit layout

- Use monochrome and highest resolution possible for your printer

The printer operator should also take this opportunity to provide feedback to the circuit designer:

- Make sure the design traces are thick enough for this process (XXmil/XXmm minimum trace width with 20mil/0.508mm minimum clearance)

- Make sure the export file is mirrored. The Laser Printer toner is going to 'transfer' to the surface of the copper clad and become unmmirrored in the process

3) Transferring the Traces to the PCB:

- Press down the glossy paper with the design onto the copper PCB

- Use a hot iron to press down glossy paper to the PCB

- After the glossy paper stick onto the PCB submerge the two in a tray of water and gently press down the paper so it peels off leaving the trace on the PCB

- Once the paper starts to peel off under the water feel free to use your finger to gently peel the paper from the copper board

- If after peeling the paper , white paper is still on the board re-dip the board into the water and rub off the remaining paper with your finger

- Dry off any water

4) Get Rid of the remaining Copper

- Place the board into a tray

- Place the Ferric Chloride Solution Bottle inside tray of hot water (this will heat the solution and make the PCB copper to be dissolved faster)

- Pour some of the solution into a tray along with your PCB

- Check the PCB every 5 or so minutes to check if the copper has been fully removed

5) Finishing Up

- Finally wash off the ink and you should be left with only copper lines on top of the traces printed